A great attendance took part in the webinar “Agile Packaging Design – Adobe Dimension & Packly: From Virtual to Real”, which involved Packly together with the Adobe Guru Michela Di Stefano, from Creative Master.

The webinar was about the Agile model concerning the packaging design process. This methodology allows, thanks to the implementation of new technologies, a better result to be achieved in less time.

The Adobe Guru presented a hypothetical case study: a customer who needs packaging for his chocolate bar brand.The participants, then, had the opportunity to discover, in practice, the operation and strategic possibilities offered by 2 tools. Adobe Dimension, a 3D rendering and design software, combined with the uniqueness of Packly’s platform.

The importance of being agile

‘With this methodology – Giuseppe Prioriello introduced the Agile model – we are going to impact on the way packaging is made, which can sometimes be really complex.”

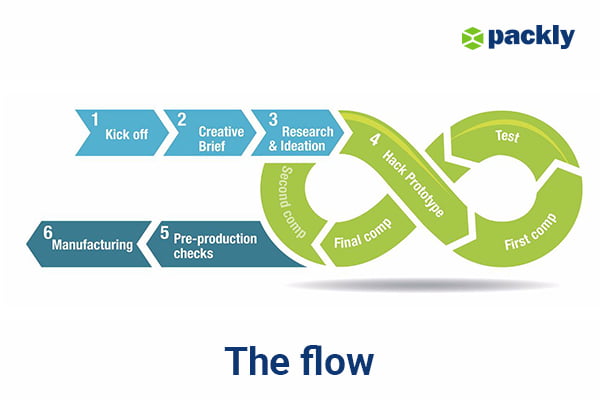

What does this mean? Giuseppe, CEO of Packly and expert in the packaging industry, explained that the process behind the creation of innovative packaging can be complex. This is due to the different steps involved in its development, which often require repetition. For this reason, it is necessary to adopt a different approach, namely the Agile approach usually used in the development world. The model is based on the creation of an MVP (Minimum Viable Product) and MMP (Minimum Marketable Product). This approach makes it possible to move quickly through the development process. And to reduce the time and costs required to achieve a functioning and market-competitive final product. Furthermore, the use of this method favors a flexible approach that can be adapted to market and customer needs, allowing changes and improvements to be made to the product quickly.

During his speech, Giuseppe also explained that when developing a product, it is important to consider:

- the quality aspect

- the user experience

Prototyping, then, is a phase in which the MVP is tested to see which features work best for the consumer. This process also includes testing the packaging, measuring the impact on sales, and iterating on the results.

Why Packly

One aid in this process is precisely technology, to speed up and simplify the process. It is here that Giuseppe proudly illustrated the uniqueness of Packly, which: “allows you to design, collaborate and print packaging, as well as manage project orders and reorders in just a few steps”.

The software is important because is where you can quickly modify the printed packaging, thanks to the ‘ability to do this with incredible speed and high quality’ – as Giuseppe specified. With Packly, all you have to do is enter the dimensions, download the template and the die layout, process it with any graphics software and upload it back to the platform as a simple PDF to visualize a 3D model in seconds. In this way, you can achieve tangible results with great ease. Special finishes such as gold, silver and raised spot varnish can be applied to the packaging, and a real-time quote can be given, allowing printing from a single piece up to 100,000 copies. Furthermore, the advantage of this process is speed, as prints can be made in as little as 48 hours.

Case history

Giuseppe then shared case histories of important customers who have used Packly, such as Dolceamaro. The confectionery company, a producer of sugared almonds, managed to ‘reinvent’ itself by releasing a new line, Tiny Donuts.

Packly made it possible to simplify the entire process. The 3D preview was shared with all the actors in the supply chain involved in the release, followed by the production of market tests, up to the final launch at points of sale.

Thanks to the platform’s potential, the customer was able to test and validate the product before sales, incredibly shortening the time-to-market. “This success,” Giuseppe comments, “has taken the company from a prototyping phase limited to a few pieces, to a production of millions of pieces.”

Conclusions

After the practical example, users also had the opportunity to interact through surveys and a ‘Q&A’ session.

The enthusiasm of those who participated was incredible, some were already aware of Packly, for others it was a discovery.

There will certainly be other opportunities to meet but, if you want to catch up with this webinar all you have to do is click on the following link myp.ac/webinar-adobe-packly and register for free.